Week 9 Capstone

- Harry Bushell

- Nov 9, 2023

- 4 min read

First week back after the ‘break’, and it’s been another solid week of productivity! Although the main thing I set out to achieve at the start of the week was back seated for next week, everything else I set out to achieve went very well. The week started with further remote working, and Monday was mainly spent creating a presentation for the pitch practice we had planned as a class for Thursday, as well as further logo and marketing work. On Tuesday I travelled back to Auckland, as I was in Christchurch for a representative hockey tournament. Then, the rest of the week was spent testing my new 3D print, testing my organic models, and planning pitch mock-ups. From these tests, I continued to iterate my prototypes, which stuck to my Gantt chart well. Outside of University, my overall health is good! Being productive over the break has put me in a solid mental place where I’m happy with my progress and feel that the workload I have coming will be manageable. Furthermore, we began our World Cup campaign and played our first friendly game on Thursday night while training on Tuesday and Saturday. Being surrounded by my best mates doing the activities I love is an excellent form of personal therapy and allows my mind to escape from the encapsulation of a capstone project.

The context of this week has been discussed accidentally in the introduction, so CARL is well and truly underway. Going straight into the action and results, this week had more testing and iterating (it’s becoming a bit of a repetition sorry).

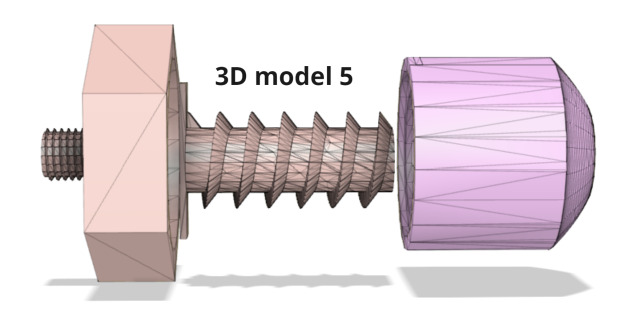

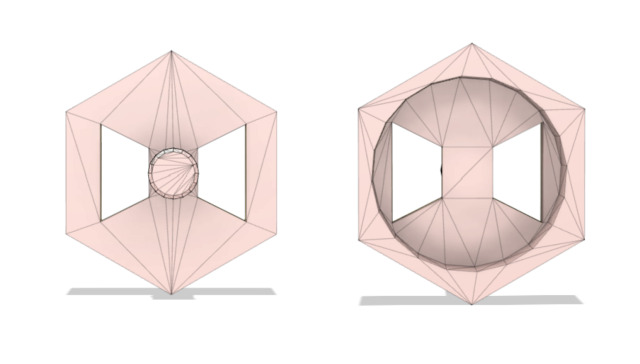

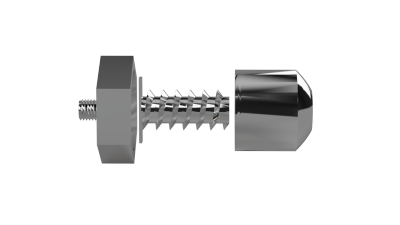

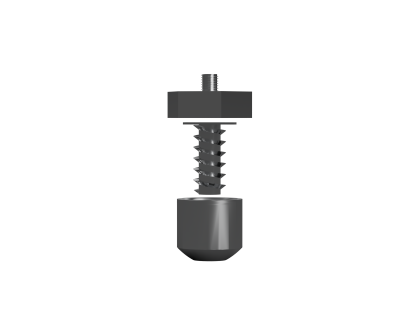

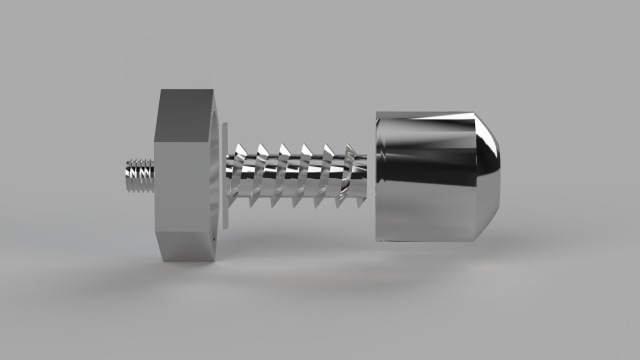

Once back in Auckland, I got straight into testing both of my prototypes! I started with my 3D print of model 4, which worked wonderfully and honestly made my day. I removed the cap (which had some issues with the thread but we move) and filled the stud with my seedmix. Once the initial leak test was passed, and the seeds stayed in the sealed system, I tested the twist mechanics and they worked wonderfully! With each twist a few seeds were transported through the stud and out of the bottom, exactly as I had planned. This proved that the new spiral design and shell both created a sealed system and a functioning one. This meant that model 5 didn’t need much in terms of iteration here. The major changes to model 5 came with a newly designed stud cap. Moving away from a screw top and instead focusing on a tightly fitting cap to close off the model. With this, there have also been cut outs incorporated to ensure that the stud can be refilled without the need of removing the lower shell, thus streamlining the refilling process further and removing the need for threads, reducing the risk of damage or accidental loss of the lower portion of the stud. Once the stud is assembled, glue can be used if needed to ensure that the cap and shell aren't separated, although from previous tests I feel that the tightness of the print should be enough. The shell remained unchanged apart from removing the outer thread, and the spiral mechanic had it’s support changed from a cross to a straight rectangle to increase space for refilling the stud and to reduce materials used.

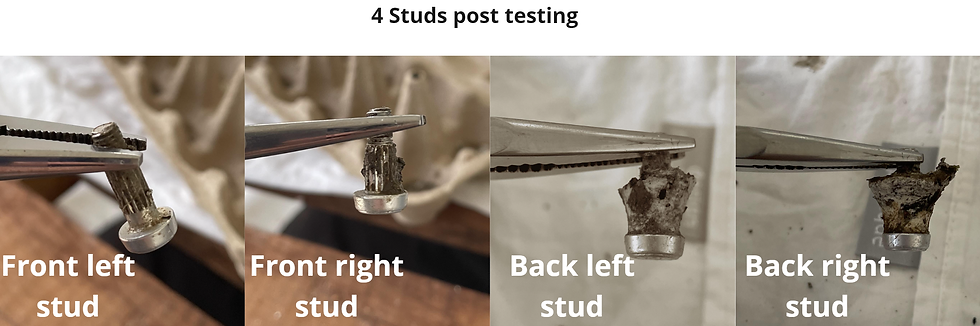

In terms of my organic stud models, the results after testing mix 2 were extremely promising. I spent 15 minutes running on slightly damp grass with the boots on, doing directional cuts and other movements common with a game of football, and as seen above, the studs more or less degraded, but not until around the 15 minute mark. This is exactly what I wanted after mix 1s durability being too low. a 15-20 minute lifespan is perfect for allowing enough time for a game to flow, while also ensuring that the studs break down enough to plant a meaningful amount of mix throughout the game. A 15 - 20 minute life span allows roughly 5-6 breaks within a game to replace the studs, which for an exhibition / event game is perfectly reasonable. With this, I think the mixture ratio for mix 2 is exactly what I wanted, and will be closely followed for the next mix (presentation mix).

Alongside the prototyping process, there was a bit of planning here and there, primarily focused on the other deliverables outside of my prototypes. This included video structure and planning for our video deliverable, mock-up image planning for my casebook, and further structure work for my visual summary.

From all of this, I continued to learn and improve with 3D modelling and 3D printing, as well as learning that nothing is ever going to be perfect, and I need to be ok with leaving certain parts of this project as they are in order to progress in other areas. I have thoroughly enjoyed the prototyping and testing period of this project, but as the Gantt chart plan for prototyping time is coming to an end, I need to move on from this side of the project and focus on the other deliverables. This is difficult for me as I’m moving away from working with things I’m confident with, to things I’m not. However, I’m aware of my struggles with the graphical side of design and will try my best to chuck myself in the deep end, and not be scared to fail. I’m hoping that I can ride the high of prototyping into this graphical journey and continue to be productive and to produce work that I’m proud of.

Comments