Week 7 Capstone

- Harry Bushell

- Nov 9, 2023

- 6 min read

Wow, wow, wow, we are more or less halfway through! As terrifying as that is, it’s also an exciting milestone for my university journey and my capstone project. Week 7 has been fantastic for the most part, despite a few hiccups here and there. Again I’ve managed to stick closely to my Gantt chart and weekly planner. However, I’ve put the ball development on hold as I focus more on testing and iterating my stud concepts, as I believe this will allow me to achieve a greater end result with the time restrictions present. This closely follows my Plan B section regarding scope and final deliverables. Week 7 focused mostly on testing and documenting, as well as iterating my previous prototypes after said testing. I really enjoy this part of any project, so getting to learn and innovate my own ideas is great fun. Outside of university, this week has been great, it was the last week of the football season so I’ve got my evenings back now which is nice! Football didn’t go our way this week, and in all honesty I’m pretty glad the club season is over. We begin our University World Cup trainings on the 16th of September which I’m really looking forward to! I’m also going away for part of week 8 and week 9 to play hockey which is something else to be excited for! I’ve planned for week 8 to focus on research and computer development stuff so that I can still get some solid work done despite being away from campus and my flat.

CARL is here once again to help structure this reflection, his assistance is greatly appreciated. The context of this week was to test, learn, and test again. It was a very prototype heavy week on both my Gantt chart and weekly planner, and focused on getting my ideas into my hands so I could have some hands-on learning and really gain an understanding of my concepts. Week 7 was heavily reliant on the prototypes I created in week 6, and through proper testing and experimenting, I hoped that week 7 would lead to some valuable iterations as well as proof of concept.

I’m going to mix the action and results paragraph into one here, as they work well with each other during prototyping phases - the actions I take are in response to the results I get. To ensure that week 7 was successful and beneficial I tested, innovated, created, and tested again. The week started with testing the prototypes I had created in week 6, I tested and documented my first StudShell prototypes (the natural degrading studs). The physical tests for my first SeedShell mix prototypes went very well. The proof of concept, feasibility and validation of my idea were all proven (apart from the growing part but due to time restraints that part is assumed). The studs hold up well enough to attach and function with the boots, but also breakdown once used on a slightly wet grassy surface. Along with this, the aluminum cores are left behind and new shells can easily be replaced by sliding them onto the unscrewed core. Besides the proof of concept, mix 1 definitely had its flaws. The first came from a few of the original models crumbling due to not being compressed enough in the molding process (an easy enough fix). A more potent flaw was the fact that the majority of the SeedShells only held up for about a minute before breaking down. This is positive in terms of showing that the breaking down part works, and also would allow for more shells to be used during a game, however a minute is well short of what is feasible for any form of football game - even if for an exhibition. Players having to replace the shells every minute or so would result in a slow and boring process. In order to combat this, my next prototype mix will incorporate a greater part clay (starting with a 3/1 ratio of compost to clay rather than a 5/1 ratio) to ensure greater structural integrity for the shells, hopefully expanding their lifespan to a more reasonable amount of time. I will continue to test my future mixes until a structural balance and reasonable ratio is acquired to move forward with. Along with this, after looking at my SeedShell prototypes closer,I realised that some of the recycled aluminum cores were shorter, resulting in some of the molds having a lot less thread showing at the top. This is due to studs commonly coming in 3 different lengths, 11mm, 13mm, and 15mm. I had created a mold for a 15mm stud, as this allowed for the most seed mixture. What I didn't account for was my array of recycled cores, which is a mix of 13mm and 15mm. Therefore I thought it smart to create a new mold, this time out of spare clay, to accommodate for both sizes of cores I have.

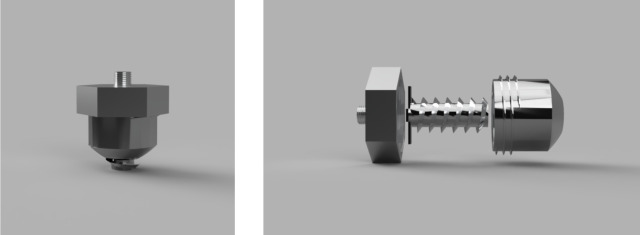

I also tested and iterated the 3D printed model of my SeedSculpt studs (the mechanical model). After testing, my 3D model definitely needs further iteration. Although the testing proved that my idea works, the gaps at the bottom of the stud are too big, and the angles of the groves aren't dramatic enough to restrict the flow of material through the stud. The twisting mechanic worked to carry material that was embedded into its groves, but the majority of material fell straight through the stud due to the gaps between the twist mechanic and the stud. Creating more dramatic angles for my twist mechanic, similar to the 3D model of my first prototype, could reduce the space for material to fall through. With this, I restructed the three key components of my 3D model. Firstly, I found that the thread I had designed was too tight for the screw mechanics to function properly. In order to improve this, I widened the the gaps within the screw-top to accommodate the thread better, as well as expanding the space at the entrance of the screw-top to allow the thread to fit better and screw in easier. Then, I found that the tip of the stud was quite weak, and that the threads didn't have enough tolerance to slide easily through the screw-top. With this in mind, I added reinforcement to the end point of the stud to thicken and strengthen it, and narrowed up the thread thickness as well as made them slightly shorter to hopefully allow a more smooth screw-in transition with the screw-top. And lastly, The big change from 3D model 3 to model 4 comes from the new spiral twist piece. After testing the 3D printed prototype of model 3, I found that the twist piece I had designed wasn't fitted enough for the shell, and allowed the seeds within the shell to fall out too easily. Along with this, it didn't print especially accurately due to the complex shape of the piece, resulting in a few holes on the edges. In order to fix this, I looked back at my earlier models, and how these addressed the issues stated earlier. With this, I found that by going back to a spiral pattern the opening at the bottom of the model is closed off a lot more efficiently, allowing the seeds to better stay in the shell. In order to counter the issues I found with a spiral mechanic in model 1, I thickened the central support beam as well as the ridges for the spiral itself to ensure that the model is strong enough for printing and testing. Once my new 3D model was completed, I created some rendered images using Fusion 360 to visualise how the model would look when crafted from a material like aluminum. Fusion is a very valuable tool for creating my 3D models and allowing fairly quick and effective renders, however they aren’t as visually appealing as renders I’ve seen through other programs like Octane Render. Despite this, Fusion is free through the University and pretty easy to use in terms of renders, making it a very valuable tool for me personally.

Lastly for this reflection, we have the learning part. This week the values of prototyping and testing were further hammered home, I continued to learn of the benefits of creating physical prototypes and the benefits of documenting processes and identifying flaws to further iterate and improve your work. I’ve learnt to avoid my own bias towards my own ideas, and to detach any emotional connection to them aside from passion in order to allow myself to identify flaws and not be scared to drastically change what I’ve created / come to terms with mistakes and errors I’ve made. I struggled with this early on in this degree, as once I had an idea I became very attached to seeing it finished, and wasn’t very open to others ideas for ideations or change, resulting in projects that were fairly one dimensional. Learning to listen and adopt others ideas into my work, as well as not being scared to have a bad idea has allowed me to grow massively as a designer, and has vastly improved my work as well as my ability to work in a team and provide feedback.

Comments